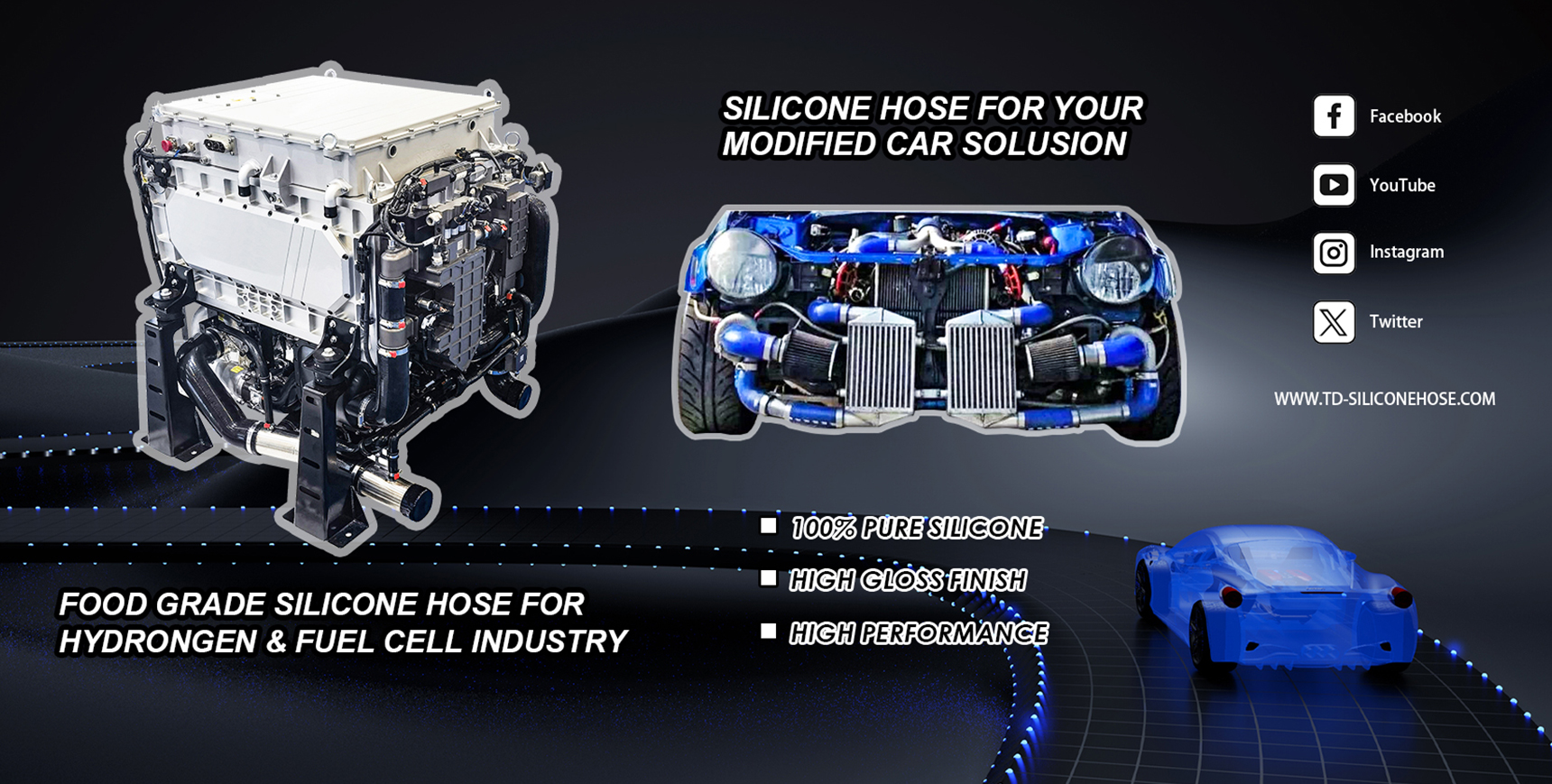

Ningbo Tiandai Auto Parts Co., Ltd. is professional China High Performance Elbow Silicone Hose Manufacturers and OEM High Performance Elbow Silicone Hose Factory. Ningbo Tiandai Auto Parts Co., Ltd. is a professional manufacturer of silicone hoses used in automobiles, trucks, motorcycles, and other machinery. The factory is located in Ningbo, the second largest port in China. It is 148 kilometers north of Shanghai and 138 kilometers west of Hangzhou, with convenient sea, land, and air transportation. TD company has strong technical strength, advanced process equipment, and specializes in producing high-quality silicone products for cooling and heating system of modified cars, racing cars,vehicles,motorcycle,bus,truck.Silicone products are IATF 16949:216 quality certified. At present, there are 9 major series and over 1500 varieties of products, which are sold to various parts of the country and exported to foreign markets. TD company has cooperated with multiple domestic hydrogen energy and fuel cell companies to customize and produce various food-grade silicone tubes for various professional water and gas pipes related to fuel cells, which have been highly praised and trusted by customers. More importantly, TD company still brimming with new ideas take to customers around the world.

Submit feedback

Silicone Vacuum Hose

High Performance & High Temperature Silicone Vacuum Hose For Transporting Air and Water Tubing Hose Vacuum Lines Kit for Automotive and Pipeline

Specifications:

- Material: Pure Silicone Rubber

- Working Temperature: - 104°F + 392°F ( - 40°C + 200°C)

- Working Pressure: 43psi

- Working Pressure: 0.3MPA - 0.9MPA

- Bursting Pressure: 100psi - 130psi

- Color: Black/Red/Blue/Customized

- Certificate: IATF 16949:2016

Silicone Hose Features:

Silicone vacuum hose is a flexible, durable tube made from silicone rubber, typically available in meter-long sections. These hoses are known for their exceptional thermal stability, flexibility, and resistance to various chemicals and environmental factors, making them ideal for a wide range of applications. Silicone vacuum hoses can withstand high and low temperatures, from -40°C to +200°C, without losing their physical properties. This makes them particularly useful in demanding environments where other materials might fail.Silicone vacuum tube is easily cut it into the appropriate length.

Versatile and adaptable, these Silicone Vacuum Hoses cater to a diverse array of needs across industries, from vacuum systems to air intake systems, and beyond. With a plethora of options in size, shape, and color, locating the ideal hose for your distinct application is effortless. Moreover, their customizable nature allows for tailored configurations to meet varied specifications and demands, ensuring seamless integration into any setup.![]()

Silicone Vacuum Hose Application:

Suitable for automotive vacuum pipe, windshield washer fluid vacuum hose, turbocharger, intake parts, etc.

Widely used in automotive vacuum lines, turbochargers, intake parts, etc., suitable for most cars, trucks, aviation or water engine compartment, this silicone vacuum hose is also suitable for aircraft and Marine engines, mainly used for air and water transport, not for oil and other fuels.![]()

What is a Silicone Vacuum Hose?

![]()

Silicone vacuum hose is a flexible, durable tube made from silicone rubber, typically available in meter-long sections. These hoses are known for their exceptional thermal stability, flexibility, and resistance to various chemicals and environmental factors, making them ideal for a wide range of applications. Silicone vacuum hoses can withstand high and low temperatures, from -40°C to +200°C, without losing their physical properties. This makes them particularly useful in demanding environments where other materials might fail.

Silicone vaccum hoses are often used in automotive, medical, food processing, and industrial applications. Their non-reactive nature ensures that they do not impart taste or odor, which is crucial for applications involving sensitive materials. Additionally, their flexibility and resilience make them easy to install and maintain, even in tight or hard-to-reach spaces.

Manufacturers of silicone vacuum hoses use various formulations to meet specific industry standards and requirements. These formulations can enhance certain properties, such as UV resistance, flame retardance, or increased flexibility. As a result, silicone straight meter hoses can be tailored to meet the exact needs of different applications, ensuring optimal performance and longevity.

What are the advantages of Silicone Vacuum Hoses over traditional rubber hoses?

Silicone vacuum hoses have significant advantages over traditional rubber hoses in several key aspects, making them the preferred material in many industrial and technological applications. First of all, silicone materials have a wide range of temperature stability and can maintain stable performance under extreme temperature conditions. Its operating temperature range can usually reach -40°C to +200°C, far exceeding the use range of traditional rubber hoses. This feature allows silicone hoses to maintain excellent elasticity and functionality in high or low temperature environments, and is not prone to deformation or failure, making them suitable for application requirements in various extreme environments.

Silicone materials have excellent chemical resistance and can resist corrosion from a variety of chemicals and solvents, including strong acids, strong alkalis, and various organic solvents, which is unmatched by traditional rubber. This feature makes silicone hoses widely used in industrial environments that require corrosion resistance and strong durability, and can withstand long-term and stable contact and use of chemicals.

In addition, silicone materials have excellent antioxidant and UV resistance, and are not easily aged and deteriorated due to long-term exposure to light or air. Compared with traditional rubber, silicone can maintain its original elasticity and durability for a longer time, thereby reducing the frequency of equipment maintenance and replacement, and improving service life and economic benefits.

The excellent softness and elasticity of silicone hoses are also one of its significant advantages. They can easily adapt to complex pipeline layouts and installation requirements while maintaining the stability of their shape and overall integrity. This feature makes the application of silicone hoses in various industrial and medical equipment more flexible and reliable, and can meet the high requirements of different equipment and systems for the flexibility and performance of hoses.

In addition, silicone materials usually have smooth surface characteristics and are not easy to adhere to dust, microorganisms or other contaminants, which helps to reduce contamination inside the system and the frequency of cleaning and maintenance. In contrast, the surface of traditional rubber can be rough and easily accumulate dirt, requiring more frequent cleaning and maintenance, adding cost and complexity to system operation.

What are the Key Applications of Silicone Vacuum Hoses?

![]()

Automotive Industry

In the automotive industry, silicone vacuum hoses are widely used due to their ability to withstand high temperatures and harsh conditions.

They are commonly found in:

Cooling Systems: Silicone cacuum hoses are used for radiator and heater hoses because they can handle the high temperatures and pressure fluctuations in engine cooling systems.

Turbochargers and Intercoolers: These hoses are ideal for connecting various components in turbocharged engines due to their heat resistance and flexibility.

Vacuum Lines and Emission Control Systems: Silicone vacuum hoses are used in vacuum lines and emission control systems due to their excellent sealing properties and resistance to chemical degradation.

Medical and Pharmaceutical Industry

Silicone vacuum hoses are highly valued in the medical and pharmaceutical industries for their biocompatibility and inertness. They are commonly used in:

Peristaltic Pumps: These hoses are ideal for use in peristaltic pumps because they do not impart any taste or odor to the fluids being pumped, ensuring the purity of pharmaceutical products.

Medical Devices: Silicone vacuum hoses are used in various medical devices, including respiratory equipment, because they are non-toxic and can be sterilized.

Laboratory Applications: Their chemical resistance makes them suitable for handling a wide range of laboratory reagents and samples.

Food and Beverage Industry

The food and beverage industry uses silicone vacuum hoses extensively due to their non-reactive nature and ability to maintain the integrity of food products. Applications include:

Food Processing Equipment: These hoses are used in food processing equipment to transport liquids and semi-liquids without contamination.

Beverage Dispensing Systems: Silicone vacuum hoses are used in beverage dispensing systems because they do not impart any flavors or odors to the beverages.

Dairy Industry: In the dairy industry, silicone vacuum hoses are used for milk transfer and other processes where hygiene and purity are critical.

How does the hardness of Silicone Vacuum Hose affect their vacuum performance?

![]()

The hardness of Silicone Vacuum Hoses is a key factor affecting their performance in vacuum systems. Hardness directly affects several important aspects of the hose in a vacuum environment, including its pressure resistance, shape stability, connection sealing performance, and long-term durability.

The hardness of the hose determines its performance under the pressure difference changes between the inside and outside of the vacuum system. A harder hose can effectively resist the effects of external pressure and reduce compression or shape changes caused by pressure changes, thereby maintaining the sealing performance of the system. This is critical for vacuum systems because any shape change or compression may cause leakage in the system, affecting its working efficiency and safety.

Appropriate hardness helps ensure a good fit between the hose and the interface of the pipe or equipment. At the connection, the hose needs to be able to fit tightly to reduce the risk of gas or liquid leakage. The sealing performance of the hose connection directly affects the operating stability and efficiency of the entire vacuum system. Therefore, choosing a hose with appropriate hardness is an important step to ensure the long-term and reliable operation of the system.

In addition, the hardness of the hose also affects its wear resistance and durability during use. Moderate hardness can make the hose more resistant to external physical damage, such as friction, impact or frequent bending. This is especially important for hoses that need to be moved or operated frequently in vacuum systems. They need to be able to maintain their structural integrity and functionality for a long time to ensure the long-term stability and safety of the system.

The choice of hose hardness will also affect the installation and maintenance process of the hose. A hose with appropriate hardness is neither too soft to be manipulated nor too hard to bend or install in a narrow space. This makes the installation and maintenance of the vacuum system easier and more efficient, reducing the potential risk of installation errors or damage.

Reinforcement Types Of Layered Fabrics:

The silicone hose boasts a durable construction, integrating either polyester,aramid or glass fiber reinforcement, providing exceptional resistance against abrasion and high temperatures.

Its robust design ensures longevity, capable of withstanding prolonged usage without succumbing to physical wear and tear.![]()

Reinforcement Layer Types:

The outside of the inner layer is usually wrapped with one or more layers of reinforcing fibers, such as Mesh Polyester Fibers, Dense Polyester,Nomex/Aramid Fibers and Glass Fibers.

These reinforcing fibers have high strength and modulus to effectively withstand internal pressure while increasing the overall rigidity and durability of the hose.![]()

Nomex/Aramid Rinforcement Layer:

Nomex/Aramid is a high-performance synthetic fiber known for its high strength, high modulus and light weight. This fiber has very strong wear resistance and can significantly improve the wear resistance of the hose.

Inside the silicone hose, aramid fibers are usually arranged in a spiral or braided form to form a reinforcement layer. This structure not only improves the wear resistance of the hose, but also enhances its overall mechanical strength

Aramid reinforced silicone hose can maintain its wear resistance over a wide temperature range and remain stable even in high temperature environments, which further extends the service life of the hose.

Both aramid fiber and silicone materials have good aging resistance, which means that after long-term use, the wear resistance of the hose will not decrease due to aging.

Nomex/Aramid reinforced silicone hose can be customized with different reinforcement layers and structures according to different application requirements to meet specific wear resistance requirements.

![]()

Hose Material Suitability and Performance:

![]()

Steel Ring Reinfored Silicone Hose:

The steel wire-reinforced silicone hose is external or internal covered with high-strength steel wire, allowing it to withstand higher pressures, ensuring the product's stability and reliability under various working conditions. This design not only enhances the pressure resistance of the hose but also effectively prevents extrusion and deformation of the hose, extending its service life.

Embedded within the walls of silicone hoses, the metal wire reinforcement forms a robust mesh structure. This structure not only enhances the overall strength of the hose but also significantly improves its pressure resistance capabilities. Under high-pressure or negative pressure conditions, the metal wire layer effectively distributes and absorbs pressure, preventing the hose from being squeezed, deformed, or collapsed. This ensures that the hose maintains a stable shape and performance under a wide range of operating conditions.![]()

Highly specialised Fluorosilicone FVMQ product for Oils/Oil mists and fuel filter hoses:

Fluorosilicone hoses use a specially compounded silicone called FVMQ (Fluorosilicone Rubber). This comes in the form of a lining of Black Fluorosilicone, covered with reinforced polyester and pure silicone.

This grade is specially formulated to prevent oil from penetrating the wall.

Fluorosilicone hose the temperature range is between -50 °C/-122 °F and +175 °C/+347 °F.

Some formulations will work under high temperature situations up to 225°C giving it excellent thermal stability making it ideal for charge air cooler and turbo hoses.![]()

Food-Grade Silicone Hose:

Application: Food-grade silicone hose for fuel cell

The advancement of food-grade silicone hoses tailored for fuel cell and hybrid vehicles marks a pivotal stride in automotive technology.

These hoses are meticulously engineered to cater to the unique demands of clean energy vehicles, particularly in facilitating the seamless filling of hydrogen and the circulation of cooling water vital for fuel cell operation.

Their design incorporates flame-retardant properties to ensure safety under conditions, alongside low conductivity characteristics to prevent any electrical interference.

Moreover, the transparency of these hoses is optimized to allow the unimpeded flow of high-purity cooling water, safeguarding the functionality of fuel cells without compromise.

![]()

Difference Cover Styles For Silicone Hose:

1.Matte Surface Silicone Hose

The main function of the outer matte silicone hose is to increase the friction of the outer layer, enhance the firmness and sealing of the silicone tube and its connecting components.

Matte silicone hose has stronger wear and aging resistance, and has pressure resistance and temperature resistance. Silicone hose can be used for a long time in harsh environments.

2.Aluminum Wrapped Silicone Hose

Aluminum-wrapped silicone hose is wrapped with aluminum material to achieve stable internal and external temperatures.

Regardless of the high temperature of the internal medium or changes in the external environment, the aluminum-coated silicone hose can effectively maintain a stable temperature.

This special design not only allows it to withstand high temperatures but also resists the impact of the external environment on the internal temperature, thereby ensuring the stability and reliability of the system.

Compared with traditional silicone hoses, aluminum-wrapped silicone hoses perform better under high temperature and high-pressure conditions.![]()

Heat Shrink Braided Sleeve Hydraulic Hose Protector:

Heat shrink braided sleeves are made of PET-DTY and HDPE materials. It has the smooth surface, strong tensile strength, explosion-proof and anti-corrosion, anti-wear and noise reduction, moisture absorption and dust prevention.Heat shrink braided sleeves have excellent wear resistance and flexibility.

Heat shrink braided sleeves are mainly used for wear-resistant and explosion-proof protection of hydraulic pipes, oil pipes, gas pipes, and other pipes in mechanical equipment, especially suitable for pipe fittings working in harsh environments.![]()

Customized Color Of Silicone Hose:

Personalized customized services:

We know that each customer's needs are different, so we provide personalized customized services. According to the specific needs of customers, we can tailor the specifications, materials, colors and other parameters of silicone hose to ensure that the products perfectly fit the customer's application scenarios.Whether it is small batch production or mass customization, we can respond flexibly and provide cost-effective customized solutions to meet the diverse needs of customers.![]()

What material composition and properties for the silicone hose?![]()

1.High performance silicone hose owe their exceptional performance and versatility to their unique material composition, primarily consisting of silicone rubber - a synthetic elastomer renowned for its remarkable properties. Silicone rubber is derived from silicon, a chemical element abundant in nature, which undergoes a series of polymerization processes to form a resilient and flexible material ideally suited for various industrial applications.

2.The molecular structure of silicone rubber endows it with several advantageous properties that distinguish it from other elastomers.Firstly, its inherent heat resistance is unparalleled, allowing silicone hoses to withstand extreme temperatures ranging from sub-zero conditions to elevated levels exceeding 200°C without experiencing significant degradation. This thermal stability makes silicone hoses indispensable in applications where exposure to heat is a constant factor, such as automotive engines, industrial ovens, and aerospace propulsion systems. Silicone rubber exhibits remarkable flexibility and elasticity, enabling silicone hoses to bend, twist, and flex without losing their structural integrity or compromising fluid flow. This inherent flexibility not only simplifies installation and routing within complex machinery configurations but also enhances resistance to mechanical stress and fatigue, thereby prolonging service life and minimizing the risk of premature failure. Silicone hoses boast exceptional resistance to a wide range of chemicals, oils, fuels, and solvents commonly encountered in industrial environments.

3.Unlike traditional rubber hoses, which may swell, degrade, or deteriorate upon exposure to certain fluids, silicone hoses remain inert and unaffected, maintaining their performance and reliability over extended periods. This chemical inertness makes silicone hoses the preferred choice for applications where compatibility with diverse media is essential, such as hydraulic systems, chemical processing plants, and pharmaceutical manufacturing facilities. Silicone rubber exhibits excellent electrical insulation properties, making silicone hoses suitable for use in electrical machinery and equipment. By effectively isolating electrical components from potential hazards such as moisture, dust, and contaminants, silicone hoses help ensure the safety and reliability of electrical systems, thereby minimizing the risk of malfunctions, short circuits, and electrical fires.![]()

4.In addition to their intrinsic material properties, silicone hoses can be further enhanced through the incorporation of reinforcements such as polyester or aramid fibers. These reinforcements impart additional strength, pressure resistance, and dimensional stability to silicone hoses, making them capable of withstanding higher operating pressures and mechanical loads. Reinforced silicone hoses find applications in high-performance automotive cooling systems, turbocharger installations, and hydraulic machinery where durability and reliability are paramount.

What are the unique advantages of our Silicone Hose?![]()

Point 1: High-quality silicone material

Our silicone hose are made of top-quality silicone material, which has a good reputation in the industry. This silicone material has excellent high-temperature resistance and is able to operate in a temperature range of -50°C to +250°C. This feature allows our silicone hose joints to remain stable in high-temperature environments and will not be deformed or damaged due to temperature changes. In addition, silicone materials also have good low-temperature resistance and remain flexible and elastic in extremely cold environments.

Point 2: Excellent elasticity and flexibility

Another notable feature of silicone material is its excellent elasticity and flexibility. Our silicone hose can effectively absorb impact and vibration when subjected to external forces, protecting the connection parts from damage. This feature makes our products perform particularly well in applications that require frequent bending and movement. The flexibility of silicone hose easily cope with various complex connection requirements, ensuring a stable connection whether in a narrow space or in situations that require multiple bends.

Point 3: Exquisite production technology

We have advanced production equipment and exquisite manufacturing technology, and a strict quality control system ensures the high quality of every factory product. From the selection of raw materials to the processing of finished products, we strictly control every aspect to ensure that every detail of the product meets the highest standards. Especially in the production process, we have adopted a number of innovative technologies to not only improve production efficiency, but also improve product performance and durability.

Point 4: Strict quality inspection

In order to ensure the high quality of our products, we conduct strict inspection and testing on each silicone hoses before leaving the factory. Quality control and inspection are key steps to ensure that the product meets standards and customer needs.At the same time, visual inspection and dimensional measurement are also commonly used quality control methods to ensure that the appearance and size of each silicone hose meet the design requirements. During the production process, raw materials, intermediate products and final products are strictly inspected for quality.These tests include pressure test, high temperature resistance test, anti-aging test and air leakage test. Through these rigorous tests, we ensure that each product will not have air or water leakage, cracking or other problems during use, ensure that the hose can operate stably under various working conditions. thereby providing customers with the most reliable use experience.

How to ensure the cost performance of our silicone hose?![]()

1.Independent production line:

We have our own production line and advanced production equipment, which can efficiently produce high-quality silicone hose. Through independent production, we are not only able to effectively control production costs, but also ensure that every aspect of the product is under our strict supervision. We continue to introduce advanced production technology and equipment to improve production efficiency while ensuring the high quality and performance of our products.

2.Efficient supply chain management:

We have a complete supply chain management system. From raw material procurement to finished product delivery, every link is strictly managed and controlled. Through long-term cooperation with high-quality raw material suppliers, we ensure high quality and stable supply of raw materials. In addition, we effectively reduce production and inventory costs by optimizing production processes and inventory management, thereby providing customers with more competitive prices.

3.Fast and safe logistics services:

We have cooperated with a number of logistics companies and established an extensive logistics network to ensure that products are delivered to customers quickly and safely. No matter where the customer is located, we can provide timely logistics services to ensure that the customer's production and use needs are not affected. At the same time, we provide a variety of logistics solutions, and customers can choose the most suitable logistics method according to their own needs, thereby further reducing logistics costs.

4.Personalized customized services:

We know that each customer's needs are different, so we provide personalized customized services. According to the specific needs of customers, we can tailor the specifications, materials, colors and other parameters of silicone hose to ensure that the products perfectly fit the customer's application scenarios. Whether it is small batch production or mass customization, we can respond flexibly and provide cost-effective customized solutions to meet the diverse needs of customers.

5.Professional customer services:

We always adhere to customer-centricity and provide professional and timely customer service. Our customer service team is composed of experienced professionals and can provide customers with a full range of services from product selection, technical consultation to after-sales support. No matter what problems customers encounter during use, we can provide timely solutions to ensure that customers have the best experience.

Silicone Vacuum Hose

High Performance & High Temperature Silicone Vacuum Hose For Transporting Air and Water Tubing Hose Vacuum Lines Kit for Automotive and Pipeline

Specifications:

- Material: Pure Silicone Rubber

- Working Temperature: - 40°F + 392°F ( - 40°C + 200°C)

- Working Pressure: 43psi

- Working Pressure: 0.3MPA - 0.9MPA

- Bursting Pressure: 100psi - 130psi

- Color: Black/Red/Blue/Customized

- Certificate: IATF 16949:2016

Silicone Hose Features:

Silicone vacuum hose is a flexible, durable tube made from silicone rubber, typically available in meter-long sections. These hoses are known for their exceptional thermal stability, flexibility, and resistance to various chemicals and environmental factors, making them ideal for a wide range of applications. Silicone vacuum hoses can withstand high and low temperatures, from -40°C to +200°C, without losing their physical properties. This makes them particularly useful in demanding environments where other materials might fail.Silicone vacuum tube is easily cut it into the appropriate length.

Versatile and adaptable, these Silicone Vacuum Hoses cater to a diverse array of needs across industries, from vacuum systems to air intake systems, and beyond. With a plethora of options in size, shape, and color, locating the ideal hose for your distinct application is effortless. Moreover, their customizable nature allows for tailored configurations to meet varied specifications and demands, ensuring seamless integration into any setup.![]()

Silicone Vacuum Hose Application:

Suitable for automotive vacuum pipe, windshield washer fluid vacuum hose, turbocharger, intake parts, etc.

Widely used in automotive vacuum lines, turbochargers, intake parts, etc., suitable for most cars, trucks, aviation or water engine compartment, this silicone vacuum hose is also suitable for aircraft and Marine engines, mainly used for air and water transport, not for oil and other fuels.![]()

What is a Silicone Vacuum Hose?

![]()

Silicone vacuum hose is a flexible, durable tube made from silicone rubber, typically available in meter-long sections. These hoses are known for their exceptional thermal stability, flexibility, and resistance to various chemicals and environmental factors, making them ideal for a wide range of applications. Silicone vacuum hoses can withstand high and low temperatures, from -40°C to +200°C, without losing their physical properties. This makes them particularly useful in demanding environments where other materials might fail.

Silicone vaccum hoses are often used in automotive, medical, food processing, and industrial applications. Their non-reactive nature ensures that they do not impart taste or odor, which is crucial for applications involving sensitive materials. Additionally, their flexibility and resilience make them easy to install and maintain, even in tight or hard-to-reach spaces.

Manufacturers of silicone vacuum hoses use various formulations to meet specific industry standards and requirements. These formulations can enhance certain properties, such as UV resistance, flame retardance, or increased flexibility. As a result, silicone straight meter hoses can be tailored to meet the exact needs of different applications, ensuring optimal performance and longevity.

What are the advantages of Silicone Vacuum Hoses over traditional rubber hoses?

Silicone vacuum hoses have significant advantages over traditional rubber hoses in several key aspects, making them the preferred material in many industrial and technological applications. First of all, silicone materials have a wide range of temperature stability and can maintain stable performance under extreme temperature conditions. Its operating temperature range can usually reach -40°C to +200°C, far exceeding the use range of traditional rubber hoses. This feature allows silicone hoses to maintain excellent elasticity and functionality in high or low temperature environments, and is not prone to deformation or failure, making them suitable for application requirements in various extreme environments.

Silicone materials have excellent chemical resistance and can resist corrosion from a variety of chemicals and solvents, including strong acids, strong alkalis, and various organic solvents, which is unmatched by traditional rubber. This feature makes silicone hoses widely used in industrial environments that require corrosion resistance and strong durability, and can withstand long-term and stable contact and use of chemicals.

In addition, silicone materials have excellent antioxidant and UV resistance, and are not easily aged and deteriorated due to long-term exposure to light or air. Compared with traditional rubber, silicone can maintain its original elasticity and durability for a longer time, thereby reducing the frequency of equipment maintenance and replacement, and improving service life and economic benefits.

The excellent softness and elasticity of silicone hoses are also one of its significant advantages. They can easily adapt to complex pipeline layouts and installation requirements while maintaining the stability of their shape and overall integrity. This feature makes the application of silicone hoses in various industrial and medical equipment more flexible and reliable, and can meet the high requirements of different equipment and systems for the flexibility and performance of hoses.

In addition, silicone materials usually have smooth surface characteristics and are not easy to adhere to dust, microorganisms or other contaminants, which helps to reduce contamination inside the system and the frequency of cleaning and maintenance. In contrast, the surface of traditional rubber can be rough and easily accumulate dirt, requiring more frequent cleaning and maintenance, adding cost and complexity to system operation.

What are the Key Applications of Silicone Vacuum Hoses?

![]()

Automotive Industry

In the automotive industry, silicone vacuum hoses are widely used due to their ability to withstand high temperatures and harsh conditions.

They are commonly found in:

Cooling Systems: Silicone cacuum hoses are used for radiator and heater hoses because they can handle the high temperatures and pressure fluctuations in engine cooling systems.

Turbochargers and Intercoolers: These hoses are ideal for connecting various components in turbocharged engines due to their heat resistance and flexibility.

Vacuum Lines and Emission Control Systems: Silicone vacuum hoses are used in vacuum lines and emission control systems due to their excellent sealing properties and resistance to chemical degradation.

Medical and Pharmaceutical Industry

Silicone vacuum hoses are highly valued in the medical and pharmaceutical industries for their biocompatibility and inertness. They are commonly used in:

Peristaltic Pumps: These hoses are ideal for use in peristaltic pumps because they do not impart any taste or odor to the fluids being pumped, ensuring the purity of pharmaceutical products.

Medical Devices: Silicone vacuum hoses are used in various medical devices, including respiratory equipment, because they are non-toxic and can be sterilized.

Laboratory Applications: Their chemical resistance makes them suitable for handling a wide range of laboratory reagents and samples.

Food and Beverage Industry

The food and beverage industry uses silicone vacuum hoses extensively due to their non-reactive nature and ability to maintain the integrity of food products. Applications include:

Food Processing Equipment: These hoses are used in food processing equipment to transport liquids and semi-liquids without contamination.

Beverage Dispensing Systems: Silicone vacuum hoses are used in beverage dispensing systems because they do not impart any flavors or odors to the beverages.

Dairy Industry: In the dairy industry, silicone vacuum hoses are used for milk transfer and other processes where hygiene and purity are critical.

How does the hardness of Silicone Vacuum Hose affect their vacuum performance?

![]()

The hardness of Silicone Vacuum Hoses is a key factor affecting their performance in vacuum systems. Hardness directly affects several important aspects of the hose in a vacuum environment, including its pressure resistance, shape stability, connection sealing performance, and long-term durability.

The hardness of the hose determines its performance under the pressure difference changes between the inside and outside of the vacuum system. A harder hose can effectively resist the effects of external pressure and reduce compression or shape changes caused by pressure changes, thereby maintaining the sealing performance of the system. This is critical for vacuum systems because any shape change or compression may cause leakage in the system, affecting its working efficiency and safety.

Appropriate hardness helps ensure a good fit between the hose and the interface of the pipe or equipment. At the connection, the hose needs to be able to fit tightly to reduce the risk of gas or liquid leakage. The sealing performance of the hose connection directly affects the operating stability and efficiency of the entire vacuum system. Therefore, choosing a hose with appropriate hardness is an important step to ensure the long-term and reliable operation of the system.

In addition, the hardness of the hose also affects its wear resistance and durability during use. Moderate hardness can make the hose more resistant to external physical damage, such as friction, impact or frequent bending. This is especially important for hoses that need to be moved or operated frequently in vacuum systems. They need to be able to maintain their structural integrity and functionality for a long time to ensure the long-term stability and safety of the system.

The choice of hose hardness will also affect the installation and maintenance process of the hose. A hose with appropriate hardness is neither too soft to be manipulated nor too hard to bend or install in a narrow space. This makes the installation and maintenance of the vacuum system easier and more efficient, reducing the potential risk of installation errors or damage.

Reinforcement Types Of Layered Fabrics:

The silicone hose boasts a durable construction, integrating either polyester,aramid or glass fiber reinforcement, providing exceptional resistance against abrasion and high temperatures.

Its robust design ensures longevity, capable of withstanding prolonged usage without succumbing to physical wear and tear.![]()

Reinforcement Layer Types:

The outside of the inner layer is usually wrapped with one or more layers of reinforcing fibers, such as Mesh Polyester Fibers, Dense Polyester,Nomex/Aramid Fibers and Glass Fibers.

These reinforcing fibers have high strength and modulus to effectively withstand internal pressure while increasing the overall rigidity and durability of the hose.![]()

Nomex/Aramid Rinforcement Layer:

Nomex/Aramid is a high-performance synthetic fiber known for its high strength, high modulus and light weight. This fiber has very strong wear resistance and can significantly improve the wear resistance of the hose.

Inside the silicone hose, aramid fibers are usually arranged in a spiral or braided form to form a reinforcement layer. This structure not only improves the wear resistance of the hose, but also enhances its overall mechanical strength

Aramid reinforced silicone hose can maintain its wear resistance over a wide temperature range and remain stable even in high temperature environments, which further extends the service life of the hose.

Both aramid fiber and silicone materials have good aging resistance, which means that after long-term use, the wear resistance of the hose will not decrease due to aging.

Nomex/Aramid reinforced silicone hose can be customized with different reinforcement layers and structures according to different application requirements to meet specific wear resistance requirements.

![]()

Hose Material Suitability and Performance:

![]()

Steel Ring Reinfored Silicone Hose:

The steel wire-reinforced silicone hose is external or internal covered with high-strength steel wire, allowing it to withstand higher pressures, ensuring the product's stability and reliability under various working conditions. This design not only enhances the pressure resistance of the hose but also effectively prevents extrusion and deformation of the hose, extending its service life.

Embedded within the walls of silicone hoses, the metal wire reinforcement forms a robust mesh structure. This structure not only enhances the overall strength of the hose but also significantly improves its pressure resistance capabilities. Under high-pressure or negative pressure conditions, the metal wire layer effectively distributes and absorbs pressure, preventing the hose from being squeezed, deformed, or collapsed. This ensures that the hose maintains a stable shape and performance under a wide range of operating conditions.![]()

Highly specialised Fluorosilicone FVMQ product for Oils/Oil mists and fuel filter hoses:

Fluorosilicone hoses use a specially compounded silicone called FVMQ (Fluorosilicone Rubber). This comes in the form of a lining of Black Fluorosilicone, covered with reinforced polyester and pure silicone.

This grade is specially formulated to prevent oil from penetrating the wall.

Fluorosilicone hose the temperature range is between -50 °C/-122 °F and +175 °C/+347 °F.

Some formulations will work under high temperature situations up to 225°C giving it excellent thermal stability making it ideal for charge air cooler and turbo hoses.![]()

Food-Grade Silicone Hose:

Application: Food-grade silicone hose for fuel cell

The advancement of food-grade silicone hoses tailored for fuel cell and hybrid vehicles marks a pivotal stride in automotive technology.

These hoses are meticulously engineered to cater to the unique demands of clean energy vehicles, particularly in facilitating the seamless filling of hydrogen and the circulation of cooling water vital for fuel cell operation.

Their design incorporates flame-retardant properties to ensure safety under conditions, alongside low conductivity characteristics to prevent any electrical interference.

Moreover, the transparency of these hoses is optimized to allow the unimpeded flow of high-purity cooling water, safeguarding the functionality of fuel cells without compromise.

![]()

Difference Cover Styles For Silicone Hose:

1.Matte Surface Silicone Hose

The main function of the outer matte silicone hose is to increase the friction of the outer layer, enhance the firmness and sealing of the silicone tube and its connecting components.

Matte silicone hose has stronger wear and aging resistance, and has pressure resistance and temperature resistance. Silicone hose can be used for a long time in harsh environments.

2.Aluminum Wrapped Silicone Hose

Aluminum-wrapped silicone hose is wrapped with aluminum material to achieve stable internal and external temperatures.

Regardless of the high temperature of the internal medium or changes in the external environment, the aluminum-coated silicone hose can effectively maintain a stable temperature.

This special design not only allows it to withstand high temperatures but also resists the impact of the external environment on the internal temperature, thereby ensuring the stability and reliability of the system.

Compared with traditional silicone hoses, aluminum-wrapped silicone hoses perform better under high temperature and high-pressure conditions.![]()

Heat Shrink Braided Sleeve Hydraulic Hose Protector:

Heat shrink braided sleeves are made of PET-DTY and HDPE materials. It has the smooth surface, strong tensile strength, explosion-proof and anti-corrosion, anti-wear and noise reduction, moisture absorption and dust prevention.Heat shrink braided sleeves have excellent wear resistance and flexibility.

Heat shrink braided sleeves are mainly used for wear-resistant and explosion-proof protection of hydraulic pipes, oil pipes, gas pipes, and other pipes in mechanical equipment, especially suitable for pipe fittings working in harsh environments.![]()

Customized Color Of Silicone Hose:

Personalized customized services:

We know that each customer's needs are different, so we provide personalized customized services. According to the specific needs of customers, we can tailor the specifications, materials, colors and other parameters of silicone hose to ensure that the products perfectly fit the customer's application scenarios.Whether it is small batch production or mass customization, we can respond flexibly and provide cost-effective customized solutions to meet the diverse needs of customers.![]()

What material composition and properties for the silicone hose?![]()

1.High performance silicone hose owe their exceptional performance and versatility to their unique material composition, primarily consisting of silicone rubber - a synthetic elastomer renowned for its remarkable properties. Silicone rubber is derived from silicon, a chemical element abundant in nature, which undergoes a series of polymerization processes to form a resilient and flexible material ideally suited for various industrial applications.

2.The molecular structure of silicone rubber endows it with several advantageous properties that distinguish it from other elastomers.Firstly, its inherent heat resistance is unparalleled, allowing silicone hoses to withstand extreme temperatures ranging from sub-zero conditions to elevated levels exceeding 200°C without experiencing significant degradation. This thermal stability makes silicone hoses indispensable in applications where exposure to heat is a constant factor, such as automotive engines, industrial ovens, and aerospace propulsion systems. Silicone rubber exhibits remarkable flexibility and elasticity, enabling silicone hoses to bend, twist, and flex without losing their structural integrity or compromising fluid flow. This inherent flexibility not only simplifies installation and routing within complex machinery configurations but also enhances resistance to mechanical stress and fatigue, thereby prolonging service life and minimizing the risk of premature failure. Silicone hoses boast exceptional resistance to a wide range of chemicals, oils, fuels, and solvents commonly encountered in industrial environments.

3.Unlike traditional rubber hoses, which may swell, degrade, or deteriorate upon exposure to certain fluids, silicone hoses remain inert and unaffected, maintaining their performance and reliability over extended periods. This chemical inertness makes silicone hoses the preferred choice for applications where compatibility with diverse media is essential, such as hydraulic systems, chemical processing plants, and pharmaceutical manufacturing facilities. Silicone rubber exhibits excellent electrical insulation properties, making silicone hoses suitable for use in electrical machinery and equipment. By effectively isolating electrical components from potential hazards such as moisture, dust, and contaminants, silicone hoses help ensure the safety and reliability of electrical systems, thereby minimizing the risk of malfunctions, short circuits, and electrical fires.![]()

4.In addition to their intrinsic material properties, silicone hoses can be further enhanced through the incorporation of reinforcements such as polyester or aramid fibers. These reinforcements impart additional strength, pressure resistance, and dimensional stability to silicone hoses, making them capable of withstanding higher operating pressures and mechanical loads. Reinforced silicone hoses find applications in high-performance automotive cooling systems, turbocharger installations, and hydraulic machinery where durability and reliability are paramount.

What are the unique advantages of our Silicone Hose?![]()

Point 1: High-quality silicone material

Our silicone hose are made of top-quality silicone material, which has a good reputation in the industry. This silicone material has excellent high-temperature resistance and is able to operate in a temperature range of -50°C to +250°C. This feature allows our silicone hose joints to remain stable in high-temperature environments and will not be deformed or damaged due to temperature changes. In addition, silicone materials also have good low-temperature resistance and remain flexible and elastic in extremely cold environments.

Point 2: Excellent elasticity and flexibility

Another notable feature of silicone material is its excellent elasticity and flexibility. Our silicone hose can effectively absorb impact and vibration when subjected to external forces, protecting the connection parts from damage. This feature makes our products perform particularly well in applications that require frequent bending and movement. The flexibility of silicone hose easily cope with various complex connection requirements, ensuring a stable connection whether in a narrow space or in situations that require multiple bends.

Point 3: Exquisite production technology

We have advanced production equipment and exquisite manufacturing technology, and a strict quality control system ensures the high quality of every factory product. From the selection of raw materials to the processing of finished products, we strictly control every aspect to ensure that every detail of the product meets the highest standards. Especially in the production process, we have adopted a number of innovative technologies to not only improve production efficiency, but also improve product performance and durability.

Point 4: Strict quality inspection

In order to ensure the high quality of our products, we conduct strict inspection and testing on each silicone hoses before leaving the factory. Quality control and inspection are key steps to ensure that the product meets standards and customer needs.At the same time, visual inspection and dimensional measurement are also commonly used quality control methods to ensure that the appearance and size of each silicone hose meet the design requirements. During the production process, raw materials, intermediate products and final products are strictly inspected for quality.These tests include pressure test, high temperature resistance test, anti-aging test and air leakage test. Through these rigorous tests, we ensure that each product will not have air or water leakage, cracking or other problems during use, ensure that the hose can operate stably under various working conditions. thereby providing customers with the most reliable use experience.

How to ensure the cost performance of our silicone hose?![]()

1.Independent production line:

We have our own production line and advanced production equipment, which can efficiently produce high-quality silicone hose. Through independent production, we are not only able to effectively control production costs, but also ensure that every aspect of the product is under our strict supervision. We continue to introduce advanced production technology and equipment to improve production efficiency while ensuring the high quality and performance of our products.

2.Efficient supply chain management:

We have a complete supply chain management system. From raw material procurement to finished product delivery, every link is strictly managed and controlled. Through long-term cooperation with high-quality raw material suppliers, we ensure high quality and stable supply of raw materials. In addition, we effectively reduce production and inventory costs by optimizing production processes and inventory management, thereby providing customers with more competitive prices.

3.Fast and safe logistics services:

We have cooperated with a number of logistics companies and established an extensive logistics network to ensure that products are delivered to customers quickly and safely. No matter where the customer is located, we can provide timely logistics services to ensure that the customer's production and use needs are not affected. At the same time, we provide a variety of logistics solutions, and customers can choose the most suitable logistics method according to their own needs, thereby further reducing logistics costs.

4.Personalized customized services:

We know that each customer's needs are different, so we provide personalized customized services. According to the specific needs of customers, we can tailor the specifications, materials, colors and other parameters of silicone hose to ensure that the products perfectly fit the customer's application scenarios. Whether it is small batch production or mass customization, we can respond flexibly and provide cost-effective customized solutions to meet the diverse needs of customers.

5.Professional customer services:

We always adhere to customer-centricity and provide professional and timely customer service. Our customer service team is composed of experienced professionals and can provide customers with a full range of services from product selection, technical consultation to after-sales support. No matter what problems customers encounter during use, we can provide timely solutions to ensure that customers have the best experience.

Silicone Vacuum Hose

High Performance & High Temperature Silicone Vacuum Hose For Transporting Air and Water Tubing Hose Vacuum Lines Kit for Automotive and Pipeline

Specifications:

- Material: Pure Silicone Rubber

- Working Temperature: - 40°F + 392°F ( - 40°C + 200°C)

- Working Pressure: 43psi

- Working Pressure: 0.3MPA - 0.9MPA

- Bursting Pressure: 100psi - 130psi

- Color: Black/Red/Blue/Customized

- Certificate: IATF 16949:2016

Silicone Hose Features:

Silicone vacuum hose is a flexible, durable tube made from silicone rubber, typically available in meter-long sections. These hoses are known for their exceptional thermal stability, flexibility, and resistance to various chemicals and environmental factors, making them ideal for a wide range of applications. Silicone vacuum hoses can withstand high and low temperatures, from -40°C to +200°C, without losing their physical properties. This makes them particularly useful in demanding environments where other materials might fail.Silicone vacuum tube is easily cut it into the appropriate length.

Versatile and adaptable, these Silicone Vacuum Hoses cater to a diverse array of needs across industries, from vacuum systems to air intake systems, and beyond. With a plethora of options in size, shape, and color, locating the ideal hose for your distinct application is effortless. Moreover, their customizable nature allows for tailored configurations to meet varied specifications and demands, ensuring seamless integration into any setup.![]()

Silicone Vacuum Hose Application:

Suitable for automotive vacuum pipe, windshield washer fluid vacuum hose, turbocharger, intake parts, etc.

Widely used in automotive vacuum lines, turbochargers, intake parts, etc., suitable for most cars, trucks, aviation or water engine compartment, this silicone vacuum hose is also suitable for aircraft and Marine engines, mainly used for air and water transport, not for oil and other fuels.![]()

What is a Silicone Vacuum Hose?

![]()

Silicone vacuum hose is a flexible, durable tube made from silicone rubber, typically available in meter-long sections. These hoses are known for their exceptional thermal stability, flexibility, and resistance to various chemicals and environmental factors, making them ideal for a wide range of applications. Silicone vacuum hoses can withstand high and low temperatures, from -40°C to +200°C, without losing their physical properties. This makes them particularly useful in demanding environments where other materials might fail.

Silicone vaccum hoses are often used in automotive, medical, food processing, and industrial applications. Their non-reactive nature ensures that they do not impart taste or odor, which is crucial for applications involving sensitive materials. Additionally, their flexibility and resilience make them easy to install and maintain, even in tight or hard-to-reach spaces.

Manufacturers of silicone vacuum hoses use various formulations to meet specific industry standards and requirements. These formulations can enhance certain properties, such as UV resistance, flame retardance, or increased flexibility. As a result, silicone straight meter hoses can be tailored to meet the exact needs of different applications, ensuring optimal performance and longevity.

What are the advantages of Silicone Vacuum Hoses over traditional rubber hoses?

Silicone vacuum hoses have significant advantages over traditional rubber hoses in several key aspects, making them the preferred material in many industrial and technological applications. First of all, silicone materials have a wide range of temperature stability and can maintain stable performance under extreme temperature conditions. Its operating temperature range can usually reach -40°C to +200°C, far exceeding the use range of traditional rubber hoses. This feature allows silicone hoses to maintain excellent elasticity and functionality in high or low temperature environments, and is not prone to deformation or failure, making them suitable for application requirements in various extreme environments.

Silicone materials have excellent chemical resistance and can resist corrosion from a variety of chemicals and solvents, including strong acids, strong alkalis, and various organic solvents, which is unmatched by traditional rubber. This feature makes silicone hoses widely used in industrial environments that require corrosion resistance and strong durability, and can withstand long-term and stable contact and use of chemicals.

In addition, silicone materials have excellent antioxidant and UV resistance, and are not easily aged and deteriorated due to long-term exposure to light or air. Compared with traditional rubber, silicone can maintain its original elasticity and durability for a longer time, thereby reducing the frequency of equipment maintenance and replacement, and improving service life and economic benefits.

The excellent softness and elasticity of silicone hoses are also one of its significant advantages. They can easily adapt to complex pipeline layouts and installation requirements while maintaining the stability of their shape and overall integrity. This feature makes the application of silicone hoses in various industrial and medical equipment more flexible and reliable, and can meet the high requirements of different equipment and systems for the flexibility and performance of hoses.

In addition, silicone materials usually have smooth surface characteristics and are not easy to adhere to dust, microorganisms or other contaminants, which helps to reduce contamination inside the system and the frequency of cleaning and maintenance. In contrast, the surface of traditional rubber can be rough and easily accumulate dirt, requiring more frequent cleaning and maintenance, adding cost and complexity to system operation.

What are the Key Applications of Silicone Vacuum Hoses?

![]()

Automotive Industry

In the automotive industry, silicone vacuum hoses are widely used due to their ability to withstand high temperatures and harsh conditions.

They are commonly found in:

Cooling Systems: Silicone cacuum hoses are used for radiator and heater hoses because they can handle the high temperatures and pressure fluctuations in engine cooling systems.

Turbochargers and Intercoolers: These hoses are ideal for connecting various components in turbocharged engines due to their heat resistance and flexibility.

Vacuum Lines and Emission Control Systems: Silicone vacuum hoses are used in vacuum lines and emission control systems due to their excellent sealing properties and resistance to chemical degradation.

Medical and Pharmaceutical Industry

Silicone vacuum hoses are highly valued in the medical and pharmaceutical industries for their biocompatibility and inertness. They are commonly used in:

Peristaltic Pumps: These hoses are ideal for use in peristaltic pumps because they do not impart any taste or odor to the fluids being pumped, ensuring the purity of pharmaceutical products.

Medical Devices: Silicone vacuum hoses are used in various medical devices, including respiratory equipment, because they are non-toxic and can be sterilized.

Laboratory Applications: Their chemical resistance makes them suitable for handling a wide range of laboratory reagents and samples.

Food and Beverage Industry

The food and beverage industry uses silicone vacuum hoses extensively due to their non-reactive nature and ability to maintain the integrity of food products. Applications include:

Food Processing Equipment: These hoses are used in food processing equipment to transport liquids and semi-liquids without contamination.

Beverage Dispensing Systems: Silicone vacuum hoses are used in beverage dispensing systems because they do not impart any flavors or odors to the beverages.

Dairy Industry: In the dairy industry, silicone vacuum hoses are used for milk transfer and other processes where hygiene and purity are critical.

How does the hardness of Silicone Vacuum Hose affect their vacuum performance?

![]()

The hardness of Silicone Vacuum Hoses is a key factor affecting their performance in vacuum systems. Hardness directly affects several important aspects of the hose in a vacuum environment, including its pressure resistance, shape stability, connection sealing performance, and long-term durability.

The hardness of the hose determines its performance under the pressure difference changes between the inside and outside of the vacuum system. A harder hose can effectively resist the effects of external pressure and reduce compression or shape changes caused by pressure changes, thereby maintaining the sealing performance of the system. This is critical for vacuum systems because any shape change or compression may cause leakage in the system, affecting its working efficiency and safety.

Appropriate hardness helps ensure a good fit between the hose and the interface of the pipe or equipment. At the connection, the hose needs to be able to fit tightly to reduce the risk of gas or liquid leakage. The sealing performance of the hose connection directly affects the operating stability and efficiency of the entire vacuum system. Therefore, choosing a hose with appropriate hardness is an important step to ensure the long-term and reliable operation of the system.

In addition, the hardness of the hose also affects its wear resistance and durability during use. Moderate hardness can make the hose more resistant to external physical damage, such as friction, impact or frequent bending. This is especially important for hoses that need to be moved or operated frequently in vacuum systems. They need to be able to maintain their structural integrity and functionality for a long time to ensure the long-term stability and safety of the system.

The choice of hose hardness will also affect the installation and maintenance process of the hose. A hose with appropriate hardness is neither too soft to be manipulated nor too hard to bend or install in a narrow space. This makes the installation and maintenance of the vacuum system easier and more efficient, reducing the potential risk of installation errors or damage.

Reinforcement Types Of Layered Fabrics:

The silicone hose boasts a durable construction, integrating either polyester,aramid or glass fiber reinforcement, providing exceptional resistance against abrasion and high temperatures.

Its robust design ensures longevity, capable of withstanding prolonged usage without succumbing to physical wear and tear.![]()

Reinforcement Layer Types:

The outside of the inner layer is usually wrapped with one or more layers of reinforcing fibers, such as Mesh Polyester Fibers, Dense Polyester,Nomex/Aramid Fibers and Glass Fibers.

These reinforcing fibers have high strength and modulus to effectively withstand internal pressure while increasing the overall rigidity and durability of the hose.![]()

Nomex/Aramid Rinforcement Layer:

Nomex/Aramid is a high-performance synthetic fiber known for its high strength, high modulus and light weight. This fiber has very strong wear resistance and can significantly improve the wear resistance of the hose.

Inside the silicone hose, aramid fibers are usually arranged in a spiral or braided form to form a reinforcement layer. This structure not only improves the wear resistance of the hose, but also enhances its overall mechanical strength

Aramid reinforced silicone hose can maintain its wear resistance over a wide temperature range and remain stable even in high temperature environments, which further extends the service life of the hose.

Both aramid fiber and silicone materials have good aging resistance, which means that after long-term use, the wear resistance of the hose will not decrease due to aging.

Nomex/Aramid reinforced silicone hose can be customized with different reinforcement layers and structures according to different application requirements to meet specific wear resistance requirements.

![]()

Hose Material Suitability and Performance:

![]()

Steel Ring Reinfored Silicone Hose:

The steel wire-reinforced silicone hose is external or internal covered with high-strength steel wire, allowing it to withstand higher pressures, ensuring the product's stability and reliability under various working conditions. This design not only enhances the pressure resistance of the hose but also effectively prevents extrusion and deformation of the hose, extending its service life.

Embedded within the walls of silicone hoses, the metal wire reinforcement forms a robust mesh structure. This structure not only enhances the overall strength of the hose but also significantly improves its pressure resistance capabilities. Under high-pressure or negative pressure conditions, the metal wire layer effectively distributes and absorbs pressure, preventing the hose from being squeezed, deformed, or collapsed. This ensures that the hose maintains a stable shape and performance under a wide range of operating conditions.![]()

Highly specialised Fluorosilicone FVMQ product for Oils/Oil mists and fuel filter hoses:

Fluorosilicone hoses use a specially compounded silicone called FVMQ (Fluorosilicone Rubber). This comes in the form of a lining of Black Fluorosilicone, covered with reinforced polyester and pure silicone.

This grade is specially formulated to prevent oil from penetrating the wall.

Fluorosilicone hose the temperature range is between -50 °C/-122 °F and +175 °C/+347 °F.

Some formulations will work under high temperature situations up to 225°C giving it excellent thermal stability making it ideal for charge air cooler and turbo hoses.![]()

Food-Grade Silicone Hose:

Application: Food-grade silicone hose for fuel cell

The advancement of food-grade silicone hoses tailored for fuel cell and hybrid vehicles marks a pivotal stride in automotive technology.

These hoses are meticulously engineered to cater to the unique demands of clean energy vehicles, particularly in facilitating the seamless filling of hydrogen and the circulation of cooling water vital for fuel cell operation.

Their design incorporates flame-retardant properties to ensure safety under conditions, alongside low conductivity characteristics to prevent any electrical interference.

Moreover, the transparency of these hoses is optimized to allow the unimpeded flow of high-purity cooling water, safeguarding the functionality of fuel cells without compromise.

![]()

Difference Cover Styles For Silicone Hose:

1.Matte Surface Silicone Hose

The main function of the outer matte silicone hose is to increase the friction of the outer layer, enhance the firmness and sealing of the silicone tube and its connecting components.

Matte silicone hose has stronger wear and aging resistance, and has pressure resistance and temperature resistance. Silicone hose can be used for a long time in harsh environments.

2.Aluminum Wrapped Silicone Hose

Aluminum-wrapped silicone hose is wrapped with aluminum material to achieve stable internal and external temperatures.

Regardless of the high temperature of the internal medium or changes in the external environment, the aluminum-coated silicone hose can effectively maintain a stable temperature.

This special design not only allows it to withstand high temperatures but also resists the impact of the external environment on the internal temperature, thereby ensuring the stability and reliability of the system.

Compared with traditional silicone hoses, aluminum-wrapped silicone hoses perform better under high temperature and high-pressure conditions.![]()

Heat Shrink Braided Sleeve Hydraulic Hose Protector:

Heat shrink braided sleeves are made of PET-DTY and HDPE materials. It has the smooth surface, strong tensile strength, explosion-proof and anti-corrosion, anti-wear and noise reduction, moisture absorption and dust prevention.Heat shrink braided sleeves have excellent wear resistance and flexibility.

Heat shrink braided sleeves are mainly used for wear-resistant and explosion-proof protection of hydraulic pipes, oil pipes, gas pipes, and other pipes in mechanical equipment, especially suitable for pipe fittings working in harsh environments.![]()

Customized Color Of Silicone Hose:

Personalized customized services:

We know that each customer's needs are different, so we provide personalized customized services. According to the specific needs of customers, we can tailor the specifications, materials, colors and other parameters of silicone hose to ensure that the products perfectly fit the customer's application scenarios.Whether it is small batch production or mass customization, we can respond flexibly and provide cost-effective customized solutions to meet the diverse needs of customers.![]()

What material composition and properties for the silicone hose?![]()

1.High performance silicone hose owe their exceptional performance and versatility to their unique material composition, primarily consisting of silicone rubber - a synthetic elastomer renowned for its remarkable properties. Silicone rubber is derived from silicon, a chemical element abundant in nature, which undergoes a series of polymerization processes to form a resilient and flexible material ideally suited for various industrial applications.

2.The molecular structure of silicone rubber endows it with several advantageous properties that distinguish it from other elastomers.Firstly, its inherent heat resistance is unparalleled, allowing silicone hoses to withstand extreme temperatures ranging from sub-zero conditions to elevated levels exceeding 200°C without experiencing significant degradation. This thermal stability makes silicone hoses indispensable in applications where exposure to heat is a constant factor, such as automotive engines, industrial ovens, and aerospace propulsion systems. Silicone rubber exhibits remarkable flexibility and elasticity, enabling silicone hoses to bend, twist, and flex without losing their structural integrity or compromising fluid flow. This inherent flexibility not only simplifies installation and routing within complex machinery configurations but also enhances resistance to mechanical stress and fatigue, thereby prolonging service life and minimizing the risk of premature failure. Silicone hoses boast exceptional resistance to a wide range of chemicals, oils, fuels, and solvents commonly encountered in industrial environments.

3.Unlike traditional rubber hoses, which may swell, degrade, or deteriorate upon exposure to certain fluids, silicone hoses remain inert and unaffected, maintaining their performance and reliability over extended periods. This chemical inertness makes silicone hoses the preferred choice for applications where compatibility with diverse media is essential, such as hydraulic systems, chemical processing plants, and pharmaceutical manufacturing facilities. Silicone rubber exhibits excellent electrical insulation properties, making silicone hoses suitable for use in electrical machinery and equipment. By effectively isolating electrical components from potential hazards such as moisture, dust, and contaminants, silicone hoses help ensure the safety and reliability of electrical systems, thereby minimizing the risk of malfunctions, short circuits, and electrical fires.![]()

4.In addition to their intrinsic material properties, silicone hoses can be further enhanced through the incorporation of reinforcements such as polyester or aramid fibers. These reinforcements impart additional strength, pressure resistance, and dimensional stability to silicone hoses, making them capable of withstanding higher operating pressures and mechanical loads. Reinforced silicone hoses find applications in high-performance automotive cooling systems, turbocharger installations, and hydraulic machinery where durability and reliability are paramount.

What are the unique advantages of our Silicone Hose?![]()

Point 1: High-quality silicone material

Our silicone hose are made of top-quality silicone material, which has a good reputation in the industry. This silicone material has excellent high-temperature resistance and is able to operate in a temperature range of -50°C to +250°C. This feature allows our silicone hose joints to remain stable in high-temperature environments and will not be deformed or damaged due to temperature changes. In addition, silicone materials also have good low-temperature resistance and remain flexible and elastic in extremely cold environments.

Point 2: Excellent elasticity and flexibility

Another notable feature of silicone material is its excellent elasticity and flexibility. Our silicone hose can effectively absorb impact and vibration when subjected to external forces, protecting the connection parts from damage. This feature makes our products perform particularly well in applications that require frequent bending and movement. The flexibility of silicone hose easily cope with various complex connection requirements, ensuring a stable connection whether in a narrow space or in situations that require multiple bends.

Point 3: Exquisite production technology

We have advanced production equipment and exquisite manufacturing technology, and a strict quality control system ensures the high quality of every factory product. From the selection of raw materials to the processing of finished products, we strictly control every aspect to ensure that every detail of the product meets the highest standards. Especially in the production process, we have adopted a number of innovative technologies to not only improve production efficiency, but also improve product performance and durability.

Point 4: Strict quality inspection

In order to ensure the high quality of our products, we conduct strict inspection and testing on each silicone hoses before leaving the factory. Quality control and inspection are key steps to ensure that the product meets standards and customer needs.At the same time, visual inspection and dimensional measurement are also commonly used quality control methods to ensure that the appearance and size of each silicone hose meet the design requirements. During the production process, raw materials, intermediate products and final products are strictly inspected for quality.These tests include pressure test, high temperature resistance test, anti-aging test and air leakage test. Through these rigorous tests, we ensure that each product will not have air or water leakage, cracking or other problems during use, ensure that the hose can operate stably under various working conditions. thereby providing customers with the most reliable use experience.

How to ensure the cost performance of our silicone hose?![]()

1.Independent production line:

We have our own production line and advanced production equipment, which can efficiently produce high-quality silicone hose. Through independent production, we are not only able to effectively control production costs, but also ensure that every aspect of the product is under our strict supervision. We continue to introduce advanced production technology and equipment to improve production efficiency while ensuring the high quality and performance of our products.

2.Efficient supply chain management:

We have a complete supply chain management system. From raw material procurement to finished product delivery, every link is strictly managed and controlled. Through long-term cooperation with high-quality raw material suppliers, we ensure high quality and stable supply of raw materials. In addition, we effectively reduce production and inventory costs by optimizing production processes and inventory management, thereby providing customers with more competitive prices.

3.Fast and safe logistics services:

We have cooperated with a number of logistics companies and established an extensive logistics network to ensure that products are delivered to customers quickly and safely. No matter where the customer is located, we can provide timely logistics services to ensure that the customer's production and use needs are not affected. At the same time, we provide a variety of logistics solutions, and customers can choose the most suitable logistics method according to their own needs, thereby further reducing logistics costs.

4.Personalized customized services:

We know that each customer's needs are different, so we provide personalized customized services. According to the specific needs of customers, we can tailor the specifications, materials, colors and other parameters of silicone hose to ensure that the products perfectly fit the customer's application scenarios. Whether it is small batch production or mass customization, we can respond flexibly and provide cost-effective customized solutions to meet the diverse needs of customers.

5.Professional customer services:

We always adhere to customer-centricity and provide professional and timely customer service. Our customer service team is composed of experienced professionals and can provide customers with a full range of services from product selection, technical consultation to after-sales support. No matter what problems customers encounter during use, we can provide timely solutions to ensure that customers have the best experience.

Silicone Vacuum Hose

High Performance & High Temperature Silicone Vacuum Hose For Transporting Air and Water Tubing Hose Vacuum Lines Kit for Automotive and Pipeline

Specifications:

- Material: Pure Silicone Rubber

- Working Temperature: - 40°F + 392°F ( - 40°C + 200°C)

- Working Pressure: 43psi

- Working Pressure: 0.3MPA - 0.9MPA

- Bursting Pressure: 100psi - 130psi

- Color: Black/Red/Blue/Customized

- Certificate: IATF 16949:2016

Silicone Hose Features: